Industrial Automation Course

Learn Best Industrial Automation Course from Robotriq

Access the complete course

Gain advanced PLC skills through our comprehensive training program. Learn PLC basics, programming, and automation component essentials. Develop practical knowledge essential for real-world applications in industrial automation. Join us to elevate your automation expertise and open doors to exciting career opportunities.

Language : Tamil | English

Best Industrial Automation Courses

Master the essentials of industrial automation with our comprehensive training programs. From PLC and SCADA training to robotics engineering and IIoT, we cover a wide range of topics. Gain hands-on experience in control systems, industrial maintenance, and machine learning. Elevate your skills with courses tailored to industrial safety, robotic process automation, and more. Join us and unlock your potential in the field of automation today.

Highlighting Key Topics

- PLC and SCADA Training

- Robotics Engineering and IIoT

- Control Systems and Industrial Maintenance

- Machine Learning for Industrial Automation

- Industrial Safety and Robotic Process Automation

- Hands-on Experience and Specialized Courses

- Propel Your Career in Automation Today

Course Eligibility

- Engineering graduates (any discipline)

- Working professionals in industrial automation, engineering, or related fields

- Students pursuing engineering degrees with an interest in automation

- Individuals with a basic understanding of engineering principles

- No prior experience required; beginners welcome to enroll

Top Skills You Will Learn

- Expertise in PLC programming and troubleshooting

- Proficiency in automation components and their usage

- Mastery of programming concepts like ladder diagrams

- Understanding and utilization of soft starters and variable frequency drives

- Integration of Human Machine Interface (HMI) and SCADA systems

- Effective fault finding and troubleshooting with PLC

Who should Enroll

- Aspiring automation engineers seeking foundational knowledge

- Professionals in industrial settings looking to upgrade their skills

- Students pursuing careers in robotics, PLC programming, or SCADA systems

- Anyone interested in the rapidly evolving field of industrial automation

- Professionals seeking to enhance their competitiveness in the job market

- Individuals aiming to transition into automation-related roles or industries

- 100% Placement

- Hand On Training

- Live Project

Advanced Industrial Automation Course Syllabus

- Introduction to Electrical Engineering

- Basic Concepts of Electricity

- Ohm’s Law and Kirchhoff’s Laws

- Electrical Components and Symbols

- Electrical Circuit Analysis

- Series and Parallel Circuits

- Voltage, Current, and Resistance

- Power and Energy in Electrical Systems

- Electrical Safety Practices

- Overview

- Introduction to PLC

- Advantages of PLC Control Panel

- Architecture of PLC

- Working principle of PLC

- PLC type and selection details

- Hardware configuration

- Software Explanation

- Communication details

- Online & Diagnostics

- Memory management

- Different types of Inputs and Outputs

- Concept of Digital I/O

- Concept of Analog I/O

- Concept of PLC scan cycle

- Maintenance and troubleshooting of PLC

- Selection of PLC

- Wiring of PLC

- Source type input wiring

- Sink type input wiring

- Transistor type output wiring

- Relay type output wiring

- Contactor – Latching/ Holding/ Retaining

- Timer – On delay/ OFF delay

- OLR, and SMPS

- Motor

- Necessity of Motor Starters

- Direct online starters

- Motor – Forward Reversal with Interlocks

- Star-delta Starter

- Importance of Relay

- Relay

- Latching/ Holding/ Retaining

- Relay wiring with Logic gates

- Field instruments

- Sensors

- Limit switch

- Reed switch

- Solenoid

- Actuators and much more

- Applications used in industries

- Programming Language – Ladder diagram

- Device configuration – Start / Stop CPU

- Addressing details Digital, I/O’s

- Addressing details Analog, I/O’s

- Data Types – Bool, Integer, Real, Word, Dword

- Compile –Download, Upload program

- Bit logic – NO, NC, NOT, SET, RESET, POSITIVE & NEGATIVE EDGE

- Timer – ON Delay, OFF Delay, Retentive Timer, Pulse Timer

- Counter – UP Counter, Down Counter, UPDOWN Counter

- Comparator – >, <, =

- Move Function

- Data type Conversion – ROUND, TRUNC, CEIL, FLOOR

- Math Functions – ADD, SUB, MUL, DIV, MOD, ABS, NEG

- Program control – CJ, CALL, LABEL, RETURN, MC, MCR

- Programming Language – Ladder diagram, FBD, STL

- Function Block, Functions – OB, FB, FC, DB

- Table, Cross reference

- Analog Configuration

- Analog signals 0v to 10v DC, 4mA to 20mA DC

- Adjusting gain & offset in A/D conversion

- Adjusting gain & offset in D/A conversion

- Scale function

- PID Configuration

- Real Time Clock – RTC

- High Speed Counter – HSC

- Pulse Train Output – PTO

- Libraries

- PDF conversion

- Real Time Applications

- Understanding the basic techniques of controlling an AC motor.

- Block Diagram of VFD

- How an AC drive is constructed, and how the various protection features work

- Operation of the AC drive.

- AC drive range and specification.

- Motor Nameplate – Drive

- Modes of Control

- V/F

- Speed & Torque

- Vector control

- Auto Tuning / ID Run

- Frequency Reference Setting

- Acceleration and De-Acceleration Control

- Forward and Reverse control

- Monitor / Display parameter

- Parameter Selection

- Parameter programming

- Set points

- Multi-speed control

- External speed control by Analog Input / Analog output

- Remote control

- Jogging concept

- Dynamic Braking

- Master slave concept

- Braking resistor

- Communication with PLC

- Introduction to HMI / SCADA

- Software Explanation

- Download and uploading the programs

- IP address configuration

- Making New Project

- Features of SCADA

- Difference Between SCADA and HMI

- Difference Between SCADA and PLC

- Making and Editing New Graphic Display

- Scada Tags – Memory, I/O, Discrete, Real, Integer, message

- Runtime, Development

- Animation

- Movement, Filling, Visibility, Blinking, Orientation, Height width,

- Tag creation

- Trend Details

- Real-time trend

- Historical trend

- Function Keys

- DDE / Suite link protocols

- Alarms and Events Details

- Security Control

Overview of Servo Systems

- Introduction to servo motors and drives

- Importance of servo systems in automation

Working Principle of Servo Motors

- Understanding servo motor construction and operation

- Principles of feedback control in servo systems

Types of Servo Motors

- Different types of servo motors: AC servo, DC servo, and stepper motors

- Selection criteria based on application requirements

Servo Drives and Controllers

- Functions and features of servo drives

- Programming servo controllers for motion control tasks

Servo System Setup and Configuration

- Installation and wiring of servo motors and drives

- Parameter configuration for optimal performance

Motion Control Programming

- Programming motion profiles for servo motors

- Trajectory planning and motion synchronization

Applications of Servo Systems

- Industrial applications of servo systems in robotics, CNC machining, and packaging

- Case studies and examples of servo-controlled systems

Troubleshooting and Maintenance

- Common issues and troubleshooting techniques in servo systems

- Preventive maintenance practices for prolonged system lifespan

Internet of Things (IoT) in Industrial Automation

Introduction to IoT

- Definition and concept of IoT

- Evolution and significance of IoT in industrial automation

Components of IoT Ecosystem

- Sensors and actuators

- Communication protocols (e.g., MQTT, CoAP)

- Edge devices and gateways

IoT Architecture

- Layers of IoT architecture (Perception, Network, Middleware, Application)

- Role of cloud computing in IoT

Integration of PLCs with IoT

- Interfacing PLCs with IoT devices

- Data acquisition and transmission from PLCs to IoT platforms

IoT Platforms and Solutions

- Overview of IoT platforms (e.g., AWS IoT, Azure IoT, Google Cloud IoT)

- Application development and deployment for industrial IoT

Data Analytics and Machine Learning in IoT

- Data preprocessing and analysis techniques

- Predictive maintenance and anomaly detection using machine learning algorithms

IoT Security and Privacy

- Security challenges in IoT deployments

- Best practices for securing IoT systems and data

Industrial IoT Applications and Case Studies

- Smart manufacturing

- Predictive maintenance

- Asset tracking and monitoring

- Energy management

Internet of Things (IoT) in Industrial Automation

Introduction to IoT

- Definition and concept of IoT

- Evolution and significance of IoT in industrial automation

Components of IoT Ecosystem

- Sensors and actuators

- Communication protocols (e.g., MQTT, CoAP)

- Edge devices and gateways

IoT Architecture

- Layers of IoT architecture (Perception, Network, Middleware, Application)

- Role of cloud computing in IoT

Integration of PLCs with IoT

- Interfacing PLCs with IoT devices

- Data acquisition and transmission from PLCs to IoT platforms

IoT Platforms and Solutions

- Overview of IoT platforms (e.g., AWS IoT, Azure IoT, Google Cloud IoT)

- Application development and deployment for industrial IoT

Data Analytics and Machine Learning in IoT

- Data preprocessing and analysis techniques

- Predictive maintenance and anomaly detection using machine learning algorithms

IoT Security and Privacy

- Security challenges in IoT deployments

- Best practices for securing IoT systems and data

Industrial IoT Applications and Case Studies

- Smart manufacturing

- Predictive maintenance

- Asset tracking and monitoring

- Energy management

Project Selection and Planning

- Identifying a real-world industrial automation challenge or problem to solve

- Defining project objectives, scope, and deliverables

System Design and Development

- Designing the control system architecture using PLCs, sensors, actuators, and other components

- Developing PLC programs and HMI interfaces for system control and monitoring

Hardware Installation and Integration

- Installing and wiring PLCs, sensors, actuators, and other equipment according to the project requirements

- Integrating communication networks and protocols for seamless data exchange

System Testing and Validation

- Conducting functional testing to ensure the proper operation of the control system

- Troubleshooting and debugging any issues or errors encountered during testing

Performance Optimization

- Fine-tuning the control system parameters for optimal performance and efficiency

- Implementing feedback mechanisms and control algorithms to improve system responsiveness

Documentation and Reporting

- Documenting the project design, implementation, and testing processes

- Generating comprehensive reports and presentations to communicate project outcomes

Presentation and Demonstration

- Presenting the industrial hands-on project to instructors, peers, and industry professionals

- Demonstrating the functionality and effectiveness of the control system in addressing the identified industrial automation challenge

Reflection and Learning

- Reflecting on the project experience and lessons learned

- Identifying areas for improvement and future development opportunities in industrial automation

Practical Class and Industrial Live Project

Practical Class

Direct Industry Project

Theory Class - Basic to Advanced

Theory Class - Basic to Advanced

Practical Class

Transforming Dreams into Careers: Discover Excellence at Robotriq Training Centre.

Job Opportunities

- PLC Programmer

- SCADA Engineer

- Industrial Robotics Engineer

- Automation Technician

- Control Systems Engineer

- Process Automation Engineer

- Instrumentation Engineer

- Electrical Automation Engineer

- Manufacturing Automation Specialist

- Industrial Maintenance Engineer

Job Opportunities

- Industrial Maintenance Engineer

- Industrial Control Panel Designer

- PLC/SCADA Project Manager

- Automation Sales Engineer

- Field Service Engineer (Automation)

- Robotics Integration Engineer

- PLC Software Developer

- Industrial Automation Trainer/Instructor

- HMI (Human-Machine Interface) Developer

- Industrial Cybersecurity Specialist

- IIoT (Industrial Internet of Things) Solutions Architect

Job Opportunities

- Industrial Network Engineer

- Motion Control Engineer

- CNC Automation Engineer

- Process Control Engineer

- Robotics Programmer

- Factory Automation Consultant

- SCARA Robot Technician

- PLC Hardware Engineer

- Industrial Data Analyst

- Automation Quality Assurance Engineer

Partnered with 200+ Trusted PLC, SCADA, and Robot Manufacturers.

Upcoming Batches in 2024

Upcoming Batches in Industrial Automation

- Start Date: 1 August 2024

- Location: Coimbatore / Online

Course Highlights:

- PLC, SCADA, HMI training

- Hands-on practice with industry-standard equipment

- Certification upon completion

- Placement support and career guidance

Who Should Attend?

- Engineers, Technicians, and Fresh Graduates

- Professionals looking to upskill

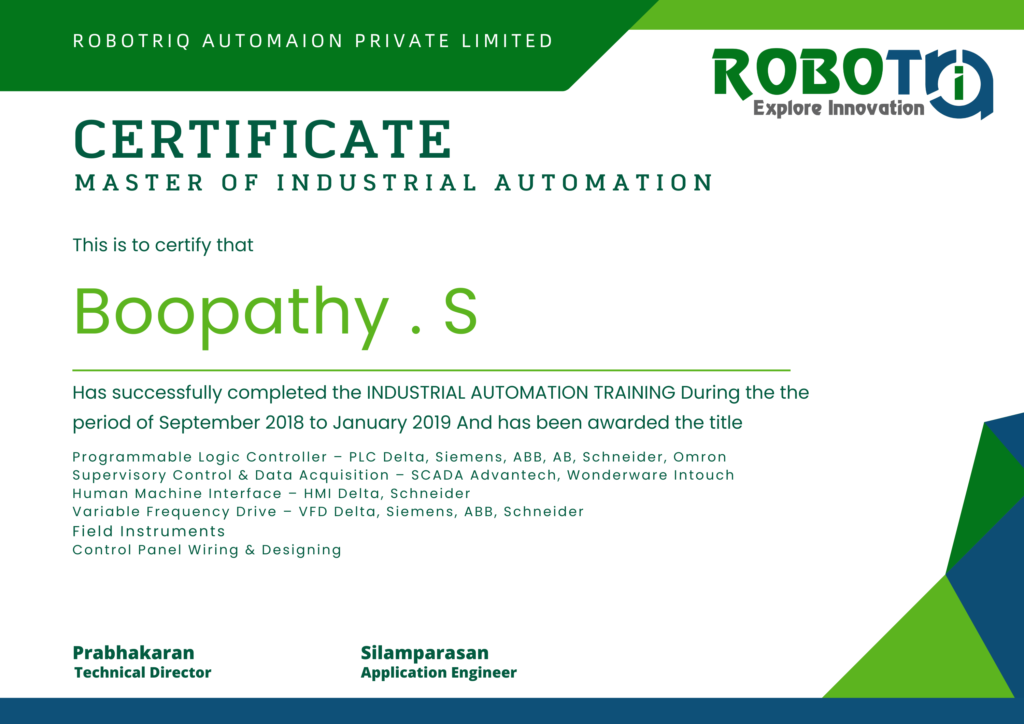

Course Certificate

Video Preview Outline: Advanced Industrial Automation Training

Change Fuji VFD Drive Parameter Setting & Wiring Class

Communication with Delta PLC & Delta HMI | SCADA

Industry Real Time Project to Client | Industry Machine PLC Programing

Student Feedback