Expert-level Troubleshooting & Maintenance in Automation

This course provides advanced training in troubleshooting and maintenance techniques essential for professionals working with industrial automation systems. Participants will gain comprehensive knowledge of Variable Frequency Drives (VFDs), Programmable Logic Controllers (PLCs), SCADA/HMI systems, Servo Motors, and Pneumatics & Field Instruments.

Language : Tamil | English

Student Rating : 4.7+ (1500 + Student)

In-demand job vacancies with over 1000+ openings await graduates of our courses

Master Troubleshooting & Maintenance with a 360° Approach

Explore advanced troubleshooting & maintenance in industrial automation with focus on VFDs, PLCs, SCADA/HMI systems, servo motors, and pneumatics. Hands-on projects and practical applications ensure mastery of essential skills for industrial settings

PLCs

Programmable Logic Controllers for automation.

VFDs

Variable Frequency Drives for motor control.

SCADA/HMI

SCADA/HMI for monitoring and control.

Servo Motors

Precision motors for motion control.

Pneumatics

Air-based systems for automation.

Field Instruments

Devices for measurement and control.

Designed for working professionals and freshers like you

Flexible Learning

Access course materials anytime, anywhere through online videos led by renowned faculty.

Networking Opportunities

Interact with peers sharing similar interests to expand your professional network.

Expert-level Troubleshooting & Maintenance in Automation

- Duration : 3 Month

- Review : 4.9+

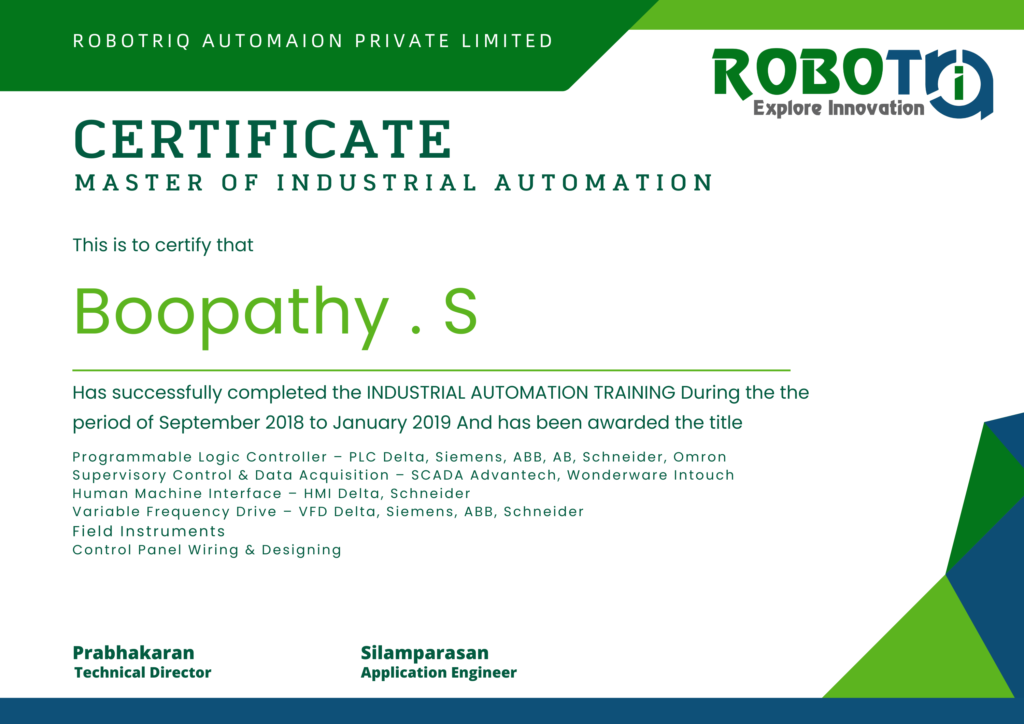

Advanced Automation Systems Certification

Benefits of the Advanced Automation Systems Certification include enhanced career prospects, validation of expertise, advanced skills development, industry recognition, and expanded professional network

Detailed Syllabus

Syllabus to Expert-level Troubleshooting & Maintenance in Automation

- Introduction to automation in manufacturing and process industries

- Evolution and significance of automation systems

- Role of troubleshooting and maintenance in enhancing system reliability

Fundamentals

- Basic principles of VFD operation

- Types of VFDs and their applications

Selection and Installation

- Criteria for selecting VFDs based on load characteristics

- Installation guidelines and considerations

Parameterization and Commissioning

- Programming VFD parameters for optimal operation

- Load testing and commissioning procedures

Interfacing with PLCs

- Integration of VFDs with Programmable Logic Controllers

- Communication protocols and data exchange methods

Advanced Topics

- Speed modulation techniques

- Error codes interpretation and troubleshooting strategies

- Real-time interface with Human Machine Interfaces (HMIs)

Introduction and Architecture

- Overview of PLC hardware and software components

- PLC scan cycle and execution sequence

Programming Fundamentals

- Ladder logic programming basics

- Addressing and configuring digital and analog I/O modules

- Programming timers, counters, and arithmetic instructions

Advanced Programming

- PID control mode implementation

- Network configuration and communication drivers

- PLC troubleshooting techniques and debugging strategies

Specialized Functions

- Servo motor control using PLCs

- Integration with SCADA systems for data visualization

SCADA Fundamentals

- Overview of SCADA systems and their role in industrial automation

- Configuration of database images and object creation

HMI Design and Configuration

- Creating dynamic graphical interfaces

- Alarm and event configuration

- Real-time and historical trend analysis

Integration with PLCs

- Establishing communication between SCADA/HMI and PLCs

- OPC/ODBC connectivity for data exchange

Introduction and Construction

- Basics of servo motor operation

- Types of servo motors and their characteristics

Control Modes

- Speed, position, and torque control modes

- Programming servo drives using PWM and other control techniques

Applications and Advantages

- Industrial applications of servo motors

- Advantages over conventional motors (e.g., induction motors)

Troubleshooting and Maintenance

- Common servo motor issues and error code interpretation

- Periodic maintenance procedures and best practices

Pneumatics Basics

- Introduction to pneumatic systems

- Components: solenoid valves, actuators, etc.

Field Instruments

- Overview of level transmitters, flow transmitters, RTD/thermocouples

- Control valves and signal converters

Applications and Integration

- Practical applications in industrial automation

- Integration with PLCs and SCADA systems

Project Work

- Integration of VFDs, PLCs, and HMI/SCADA systems

- Servo motor control project

- Troubleshooting simulated automation scenarios

Safety Practices

- Importance of safety in industrial automation

- Compliance with industry standards and regulations

Case Studies

- Real-world case studies of successful automation implementations

- Lessons learned and best practices in industrial automation

Course Learning Pathway

Empowering Tomorrow's MNC Masters: Where Practical Skills Forge Expertise

Theory Class

Practical Class

Practical Class

Direct Industry Project

Video Preview Outline

Change Fuji VFD Drive Parameter Setting & Wiring Class

Communication with Delta PLC & Delta HMI | SCADA

Industry Real Time Project to Client | Industry Machine PLC Programing

Job Opportunities After Course

- Automation Maintenance Technician

- Control Systems Engineer

- Maintenance Supervisor

- Field Service Engineer

- Automation Specialist

- Industrial Electrician

- PLC Programmer

- SCADA Operator

- Instrumentation Technician

- Robotics Engineer

Job Opportunity Industries

- Manufacturing

- Automotive

- Aerospace

- Medical Devices

- Electronics

- Pharmaceutical

- Food and Beverage

- Packaging

- Building Automation

- Water and Wastewater Treatment

Job Opportunity Countries

- India

- China

- United States

- Germany

- Gulf

- Australia

- France

- Canada

- South Korea

- Japan

Partnered with 200+ Trusted PLC, SCADA, and Robot Manufacturers.

Upcoming Batches in 2024

Upcoming Batches in Industrial Automation

- Start Date: 1 August 2024

- Location: Coimbatore / Online

Course Highlights:

- PLC, SCADA, HMI training

- Hands-on practice with industry-standard equipment

- Certification upon completion

- Placement support and career guidance

Who Should Attend?

- Engineers, Technicians, and Fresh Graduates

- Professionals looking to upskill

Student Feedback