Industrial Maintenance Engineer Training

The Industrial Automation Maintenance Engineers Training course covers fundamentals of automation and maintenance through 10 modules. Students will engage in hands-on projects and real-world examples, learning about maintenance schedules, electrical circuits, VFD drives, SCADA systems, and troubleshooting. The course emphasizes practical skills and project-based learning.

Language : Tamil | English

Student Rating : 4.7+ (1500 + Student)

Maintenance Engineer Training Overview

Best Industrial Demand : Maintenance Engineers

The Industrial Automation Maintenance Engineers Training course focuses on essential automation and maintenance skills across 10 modules. Through practical projects and real-world scenarios, students learn about maintenance scheduling, electrical circuits, VFD drives, SCADA systems, and troubleshooting techniques. This hands-on approach ensures learners gain practical skills applicable in diverse industrial settings, preparing them for challenges in modern automation environments.

Job Opportunities After Industrial Robotics Training

Factory Automation Course syllabus

Syllabus to Factory Automation Course Certificate

Advanced Factory Automation Course Syllabus

Learning Modules:

- Basics of Industrial Automation

- Importance of Maintenance in Automation Activities:

- Interactive Lecture

- Group Discussion on the role of automation in daily life

- Simple project: Building a basic automated system using everyday materials

Learning Modules:

- What is a Maintenance Schedule?

- Importance of Regular Maintenance Activities:

- Interactive Lecture

- Case Study Analysis: Consequences of poor maintenance

- Project: Create a simple maintenance schedule for a household appliance

Learning Modules:

- Introduction to Electrical Circuits

- Components of Control Circuits Activities:

- Hands-on Workshop: Building a basic circuit using batteries and bulbs

- Group Activity: Identifying components in a circuit diagram

- Project: Design a simple control circuit for a toy

Learning Modules:

- Reading Electrical Drawings

- Common Symbols and Their Meanings Activities:

- Lecture on Electrical Drawings

- Practice Exercise: Interpreting basic electrical diagrams

- Project: Create an electrical drawing for a simple circuit

Learning Modules:

- What is a VFD Drive?

- How VFD Drives are Used in Motors Activities:

- Demonstration: Installing a VFD drive on a small motor

- Group Discussion: Benefits of VFD drives in automation

- Project: Install and test a VFD drive on a small motor

Learning Modules:

- Introduction to Current Control

- Methods of Controlling Current in Motors Activities:

- Lecture on Current Control Techniques

- Lab Exercise: Experimenting with current control on a small motor

- Project: Create a simple setup to control the current in a motor

Learning Modules:

- What is SCADA?

- How SCADA is Used in Energy Monitoring Activities:

- Interactive Lecture

- Hands-on Workshop: Setting up a basic SCADA system

- Project: Implement a SCADA system to monitor energy usage in a model setup

Learning Modules:

- Common Problems in Automation Systems

- Basic Troubleshooting Techniques Activities:

- Lecture on Troubleshooting Methods

- Simulation Exercise: Diagnosing faults in a simulated system

Learning Modules:

- What are SERVO Motors?

- Basics of SERVO Drive Parameter Settings Activities:

- Demonstration: Setting parameters on a SERVO drive

- Group Discussion: Applications of SERVO motors in automation

- Project: Configure and test a SERVO motor setup

Learning Modules:

- Types of Control Instruments

- Wiring and Maintenance Techniques Activities:

- Lecture on Instrument Controls

- Hands-on Workshop: Wiring sensors and controllers

- Project: Design and maintain a control system for a small process setup

Learning Module:

- Importance of Earthing in Industrial Automation

- Types of Earthing Systems

- Earthing Techniques for Different Equipment

- Safety Considerations in Earthing Practices

Advanced Industrial Automation Maintenance Training

Manufacturing Sector

Enhances operational efficiency and reduces downtime through optimized automation maintenance practices.

Energy Sector

Ensures reliable performance and safety of automated systems in power generation and renewable energy facilities.

Automotive Industry

Improves production line efficiency and quality control by maintaining advanced automation technologies.

Aerospace

Supports critical systems reliability and compliance with stringent safety standards through meticulous automation maintenance.

Industrial Robotics Course Learning Pathway

Empowering Tomorrow's MNC Masters: Where Practical Skills Forge Expertise

Theory Class

Practical Class

Practical Class

Direct Industry Project

Job Opportunities After Course

- Automation Maintenance Technician

- Control Systems Engineer

- Maintenance Supervisor

- Field Service Engineer

- Automation Specialist

- Industrial Electrician

- PLC Programmer

- SCADA Operator

- Instrumentation Technician

- Robotics Engineer

Job Opportunity Industries

- Manufacturing

- Automotive

- Aerospace

- Medical Devices

- Electronics

- Pharmaceutical

- Food and Beverage

- Packaging

- Building Automation

- Water and Wastewater Treatment

Job Opportunity Countries

- India

- China

- United States

- Germany

- Gulf

- Australia

- France

- Canada

- South Korea

- Japan

Partnered with 200+ Trusted PLC, SCADA, and Robot Manufacturers.

Upcoming Batches in 2024

Upcoming Batches in Industrial Automation

- Start Date: 1 August 2024

- Location: Coimbatore / Online

Course Highlights:

- PLC, SCADA, HMI training

- Hands-on practice with industry-standard equipment

- Certification upon completion

- Placement support and career guidance

Who Should Attend?

- Engineers, Technicians, and Fresh Graduates

- Professionals looking to upskill

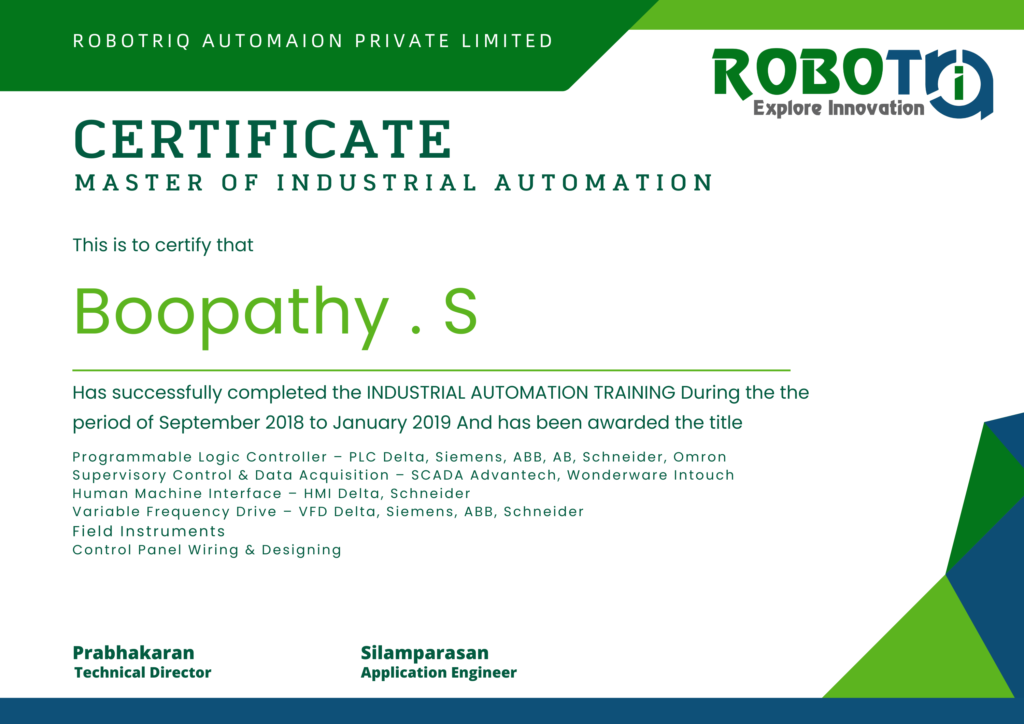

Course Certificate

Student Feedback