Industrial Robotics Course

Industrial Robotics Course: Learn programming, operation, and maintenance of robots. Covers safety, programming techniques, troubleshooting, and hands-on practice. Essential for industry professionals.

Language : Tamil | English

Student Rating : 4.7+ (1500 + Student)

Robotics Course Overview

Best Industrial Demand : Industrial Robot Automation Training

The Industrial Robotics Course offers a comprehensive understanding of robotics in industrial settings. Covering robot architecture, selection criteria, and safety precautions, students gain hands-on experience in jogging robots, programming motions, and setting up user and tool frames. Practical exercises in program testing, pick-and-place, and welding operations are included. With real-world examples and projects, learners develop essential skills for modern manufacturing. In India’s booming market, robotics professionals can expect annual salaries from INR 6 to 12 lakhs.

Job Opportunities After Industrial Robotics Training

Industrial Robotics Course syllabus

Syllabus to Industrial Robotics Programming & Maintenance Certificate

Module : 1

Introduction to Industrial Robots

Understanding the role and significance of industrial robots in manufacturing processes

Module : 2

Architecture of Robots

Delving into the structural design and components of industrial robots and overall

Module : 3

Factors Influencing the Selection of Robots

Analyzing key considerations for choosing the most suitable robots for specific tasks

Module : 4

General Safety Precautions

Highlighting essential safety measures to ensure the well-being of operators and surroundings during robot operation

Module : 5

Jogging of Robot in Joint & World Frame

Hands-on practice and theoretical understanding of jogging techniques in both joint and world frames

Module : 6

Selection & Creation of Program

Guidance on selecting appropriate programming methods and creating effective robot programs

Module : 7

Joint, Linear & Circular Motion Instructions

Comprehensive overview and practical exercises on different motion instructions for robots

Module : 8

Set up & Usage of User Frame

Instruction on setting up and utilizing user-defined coordinate frames for specific tasks

Module : 9

Tool Frame Setup & Usage

Understanding the setup and application of tool coordinate frames for precise operation

Module :10

Usage of Various Program Instructions

Exploring a variety of program instructions for versatile robot operation and automation

Module : 11

Practice on Setting Frames & Program Instruction

Hands-on practice sessions focusing on frame setting and program instruction implementation

Module :12

Explanation of I/O's & I/O Instructions

Detailed explanation and practical exercises on input/output devices and instructions for robot control

Module : 13

Program Testing, Editing & Touch Up

Techniques for testing, editing, and refining robot programs to optimize performance

Module :14

Pick & Place and Welding Operation

Instruction on programming robots for pick-and-place operations and welding tasks

Module : 15

Backup/Restoring of Data & Auto Backup

Procedures for data backup, restoration, and automatic backup features to prevent data loss

Module :16

LED Indications & Fuses on Controller

Understanding the indications provided by LED lights and the role of fuses in robot controllers

Module : 17

Maintenance of Cabinet/Battery

Maintenance guidelines including cabinet upkeep and battery replacement procedures for prolonged robot functionality

Module :18

Simple Troubleshooting & Alarm Screens

Basic troubleshooting techniques and understanding alarm screens for swift issue resolution

Industrial Robotics Course Learning Pathway

Empowering Tomorrow's MNC Masters: Where Practical Skills Forge Expertise

Theory Class

Practical Class

Practical Class

Direct Industry Project

Partnered with 200+ Trusted PLC, SCADA, and Robot Manufacturers.

Upcoming Batches in 2024

Upcoming Batches in Industrial Automation

- Start Date: 1 August 2024

- Location: Coimbatore / Online

Course Highlights:

- PLC, SCADA, HMI training

- Hands-on practice with industry-standard equipment

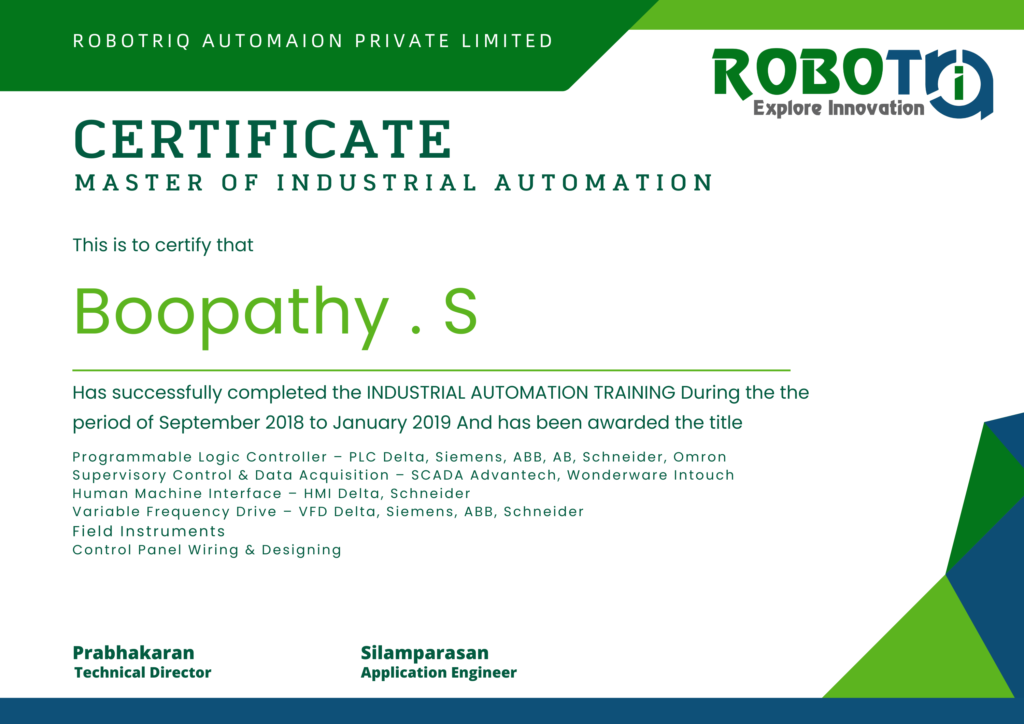

- Certification upon completion

- Placement support and career guidance

Who Should Attend?

- Engineers, Technicians, and Fresh Graduates

- Professionals looking to upskill

Course Certificate

Student Feedback