What is SCADA?

SCADA stands for Supervisory Control and Data Acquisition. It is a centralized system used to monitor, control, and analyze industrial processes across multiple locations in real-time.

Think of SCADA as the control room that gives engineers and operators complete visibility and control over an entire plant, facility, or even a network of sites.

How Does SCADA Work?

A SCADA system typically consists of:

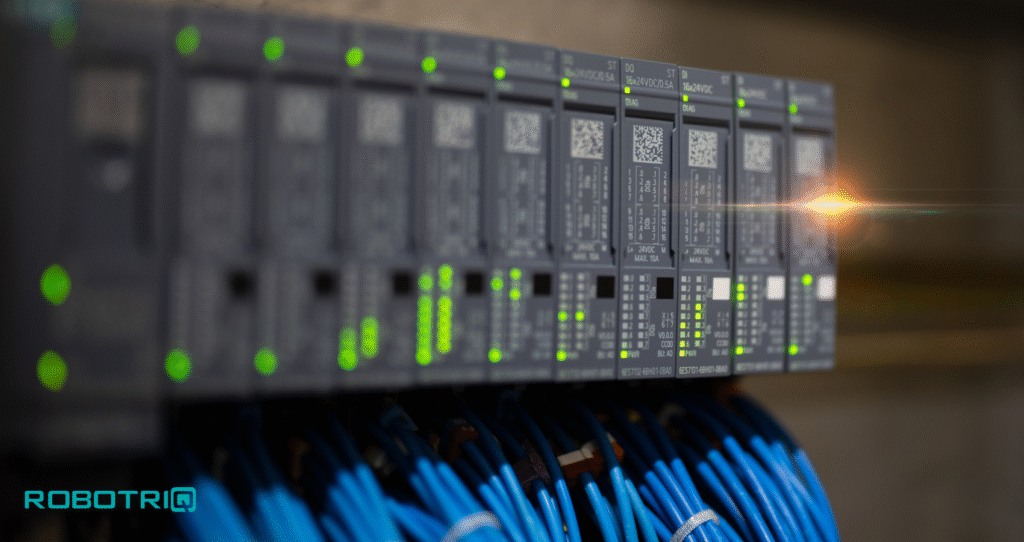

Field Devices – Sensors, PLCs, RTUs (Remote Terminal Units) collect real-time data from machines or environments.

Communication Network – Transfers data between field devices and the control center.

SCADA Software – Displays data on user-friendly interfaces like dashboards, trends, and alarms.

Operator Interface (HMI) – Allows users to monitor the system, issue commands, and make adjustments.

For example: In a water treatment plant, SCADA can show tank levels, pump status, valve positions, and chemical dosing rates — all on one screen — while allowing operators to control them remotely.

Key Features of SCADA:

Real-time data monitoring

Remote control of processes

Alarm and event management

Historical data logging and reporting

System diagnostics and troubleshooting

Where is SCADA Used?

SCADA systems are widely used in:

Power generation and distribution

Water and wastewater treatment

Oil and gas industries

Manufacturing and production plants

Transportation and infrastructure